Influence of inner and outer ring fitting accuracy of RDK tapered roller bearing on bearing temperature rise

RDK tapered roller bearing is an important supporting part of the rotating system of mechanical equipment, and the temperature rise effect in the running process of the bearing will affect the performance of the bearing. If the bearing temperature is too high, it will directly lead to the failure of the bearing, affect the rotating system of the machinery, and cause the mechanical equipment can not work normally, then the fitting accuracy of the inner and outer rings of RDK tapered roller bearing has a great influence on the temperature rise of the bearing What about the strength?

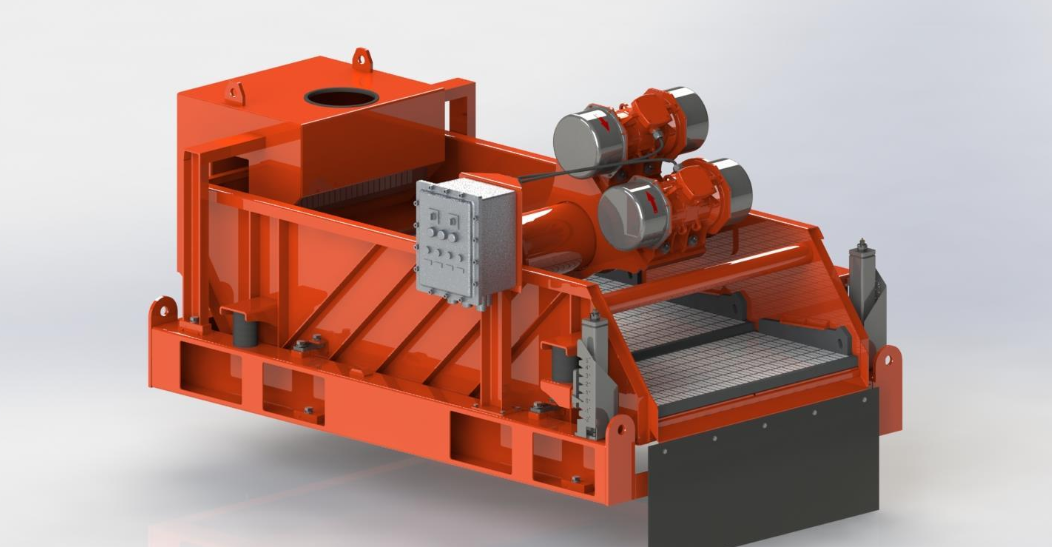

Figure 1 RDK tapered roller bearing

Six groups of tapered roller bearings with different fitting accuracy are selected by using intelligent test bench, each group contains five identical test pieces, and a total of 30 groups of tests are carried out. The test was carried out at three different speeds (1 000 R / min, 3 000 R / min, 5 000 R / min).

1. Influence of bearing outer ring fitting accuracy on balance temperature

Taking the influence of bearing outer ring fitting accuracy on balance temperature, group A, B, C and group D, e, F were compared and analyzed to study the change law of heat balance under different outer ring fitting accuracy when the inner ring fitting state of tapered roller bearing was fixed.

It can be seen from Fig. 2 that with the increase of rotating speed, the bearing balance temperature increases. When the inner ring interference is 0.005 mm, the balance temperature changes with the increase of the gap, and the temperature first decreases and then increases. When the inner ring interference is 0.005 mm and the outer ring clearance is 0.01 mm, the temperature is the lowest and the working condition is the best.

Fig. 2 Effect of outer ring fit of group A, B and C bearings on equilibrium temperature

It can be seen from Fig. 3 that with the increase of rotating speed, the bearing balance temperature increases. When the inner ring interference is 0.015 mm, the outer ring interference has little effect on the temperature. When the inner ring interference is 0.015 mm and the outer ring interference is 0.005 mm, the temperature is the lowest and the working state is the best.

Fig. 3 Effect of outer ring fit on balance temperature of D, e and f bearings

Comparing with Fig. 2 and Fig. 3, it can be seen that when the inner ring interference is small, the outer ring tightness has a more obvious effect on the bearing balance temperature; when the inner ring interference is large, the outer ring tightness has no significant effect on the bearing balance temperature.

2. Influence of bearing inner ring fitting accuracy on balance temperature

Taking group B, e and group C, f for comparative analysis, the heat balance variation law of tapered roller bearing with different inner ring fitting accuracy under a certain outer ring fitting state is studied.

It can be seen from Fig. 4 that the bearing balance temperature increases with the increase of rotating speed. When the outer ring clearance is 0.007 mm, the temperature increases with the increase of the inner ring interference, and the temperature rises faster in the low speed region (1 000 ~ 3 000 R / min), which is more affected by the inner ring interference. At the same speed, the equilibrium temperature decreases with the increase of matching value.

Fig. 4 Effect of inner ring fit of group B and e bearings on equilibrium temperature

It can be seen from Fig. 5 that with the increase of rotating speed, the bearing balance temperature increases. When the outer ring clearance is 0.02 mm, the temperature increases with the increase of inner ring interference, and in the high speed region (3 000 ~ 5 000 R / min), the inner ring interference becomes larger and the temperature rise becomes smaller.

Comparing with figure 4 and figure 5, it can be seen that when the outer ring clearance is small, the change of inner ring interference has a significant impact on the balance temperature; when the outer ring clearance is large, the change of inner ring interference has no significant impact on the balance temperature.

Fig. 5 Effect of inner ring fit of group C and f bearings on equilibrium temperature

3. Analysis results

(1) Through the intelligent detection test-bed, the relationship between the inner and outer ring fitting accuracy changes and temperature rise of tapered roller bearing is understood under the condition of bearing temperature rise under the change of fitting accuracy, and the change rules of different fitting accuracy and temperature rise are obtained: fitting accuracy has a direct impact on the temperature rise of bearing operation, and too high temperature may lead to bearing failure. In the case of different speeds, the trend of the influence of fitting accuracy on temperature rise is different.

(2) When the speed of the tested part is between 0 ~ 6 000 R / min and the inner ring is in a certain matching state, the equilibrium temperature of the tested part first decreases and then increases with the increase of the outer ring clearance, and when the inner ring interference is small, the change of the outer ring clearance has a more significant effect on the temperature rise. When the outer ring fit state is constant, the balance temperature of the tested part increases with the increase of the inner ring interference

But it increased. And in the low speed region, the temperature rise trend is faster, which is more affected by the change of inner ring interference. With the increase of outer ring clearance (0 ~ 0.02mm), the equilibrium temperature first decreases and then increases, and the clearance of about 0.01mm is the best value.

(3) During the operation of tapered roller bearing, many parameters will affect the performance of the bearing. In the speed range of 0 ~ 6 000 R / min, clearance fit should be adopted for the outer ring and interference fit should be adopted for the inner ring. Within a certain speed, the influence of the fitting accuracy of the bearing outer ring on the temperature rise will decrease with the increase of the inner ring interference.

Through the analysis, it is known that the fitting accuracy of tapered roller bearing affects the temperature rise. Therefore, it is very important to select reasonable fitting value at different speeds and reduce the temperature in the working process to improve the service efficiency and service life of the bearing.