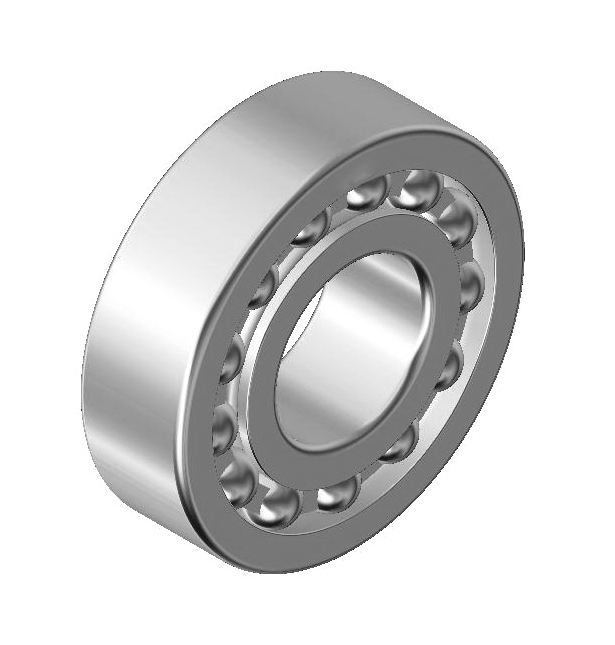

Textile machine bearing

The environment of textile bearings is very harsh, and it also requires long service life, heavy load, high speed, low noise, and stable operation. Textile machine bearings are mainly used to bear combined radial and axial loads, mainly radial loads. In the process of installation and use, the dustproof effect is good and a certain eccentric adjustment can be realized. Bearings for textile machines have a stop ring on both sides of the outer ring with sealing rings, tapered bushings, lock washers and accessories installed. It is mainly used to bear combined radial and axial loads, mainly radial loads.In the process of installation and use, the dustproof effect is good and a certain eccentric adjustment can be realized. Textile machine bearings are particularly suitable for bearing results with limited radial installation dimensions. When selecting a bearing without an inner ring or a needle roller and cage assembly, the journal surface and the surface of the housing hole that match the bearing are directly used as the inner and outer rolling surfaces of the bearing to ensure that the load capacity and running performance are the same as those of the bearing with ferrules.

Textile machine bearing use

Application field

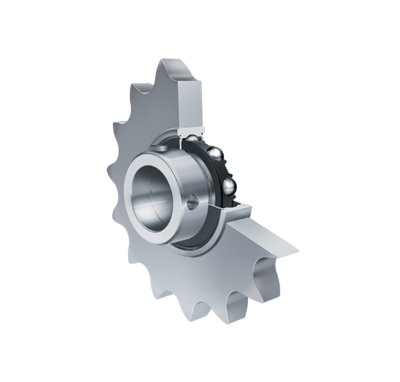

Yoke type crawler idler

In textile machinery, the hoop seat drive and sand clamping device will use idlers. The yoke track idler can transmit the rotation of the cam and the eccentric to the reciprocating motion, and has a precise definition and precise count. The outer ring of the textile bearing is made of special rolling bearing steel, and its outer wall is particularly thick. At the same time, textile bearings have optimized their outer contours, so

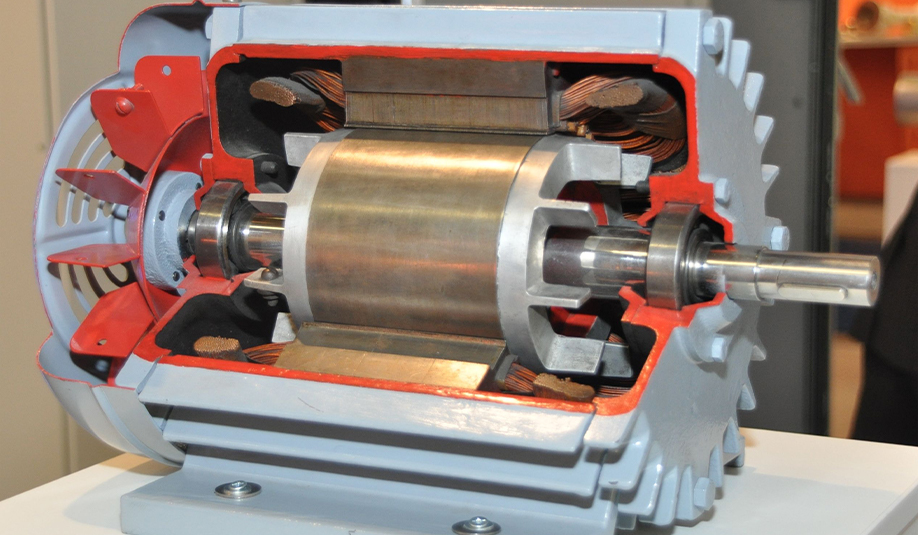

False twist bearing

The shaft unit is an integral unit, which is easy to install, does not require any adjustment, and has low operating noise. With its special top double-row ball bearing to form an integrated elastic support device, the shaft runs extremely stable.