Bearing of construction machinery

Construction machinery is an important part of the assembly industry. Generally speaking, construction machinery, road construction and maintenance, stream-type lifting and loading and unloading operations, and various construction projects are necessary for comprehensive mechanized construction engineering machinery equipment (called engineering machinery). It is mainly used as raw materials for construction, transportation, national defense construction, energy industry, mine construction and production, such as construction and industrial production, agriculture, forestry and water conservancy construction, industrial and civil construction, urban construction, environmental protection, etc. field.Slewing mechanism

The slewing mechanism is composed of two parts: a rotating bearing device and a rotating drive device. Rotating part

Difference mechanism

Differential mechanism can make the left and right (or front and rear) drive wheels at different speeds...

Drive bevel gear shaft

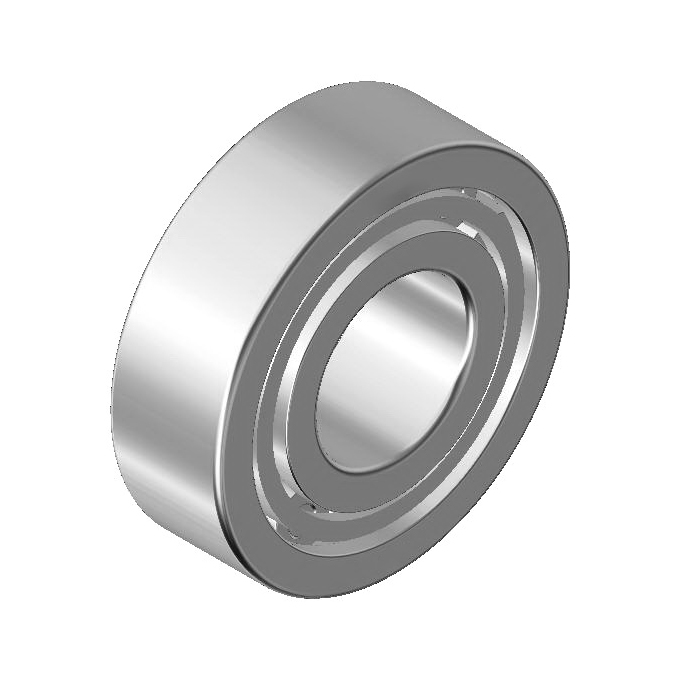

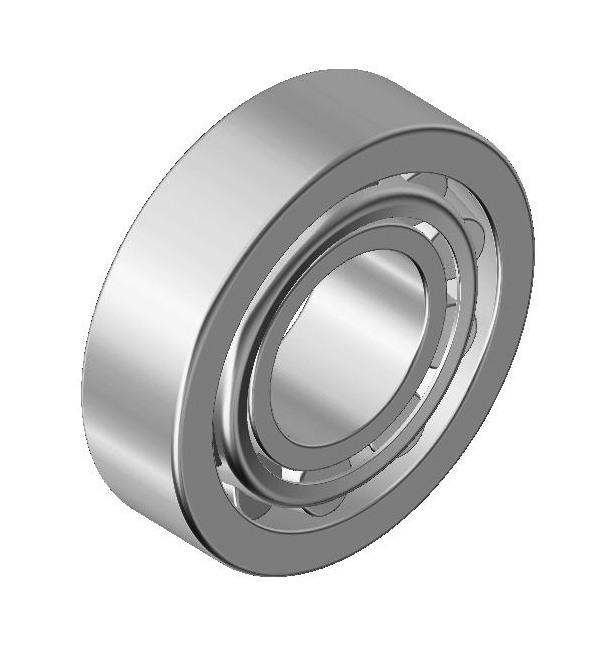

RDK tapered roller bearings and cylindrical roller bearings can provide a full range of applications.

Wheel hub

Wheel hub bearing bears the force generated by the gravity of the vehicle, the axial force and the impact force of the bearing.