Wind power bearing

Wind power is a clean energy that does not produce carbon dioxide that can cause the greenhouse effect, and wind power is rapidly spreading in countries around the world. Large-scale wind turbines (windmills) are huge machinery. Many 2MW-class wind power generation equipment under construction now have windmill blades about 40 meters long, a rotating shaft height of 60 to 100 meters, and a total weight of no less than 200 tons. Therefore, the bearings used in windmills must also be large, with an inner diameter ranging from 100 mm to 700 mm. Some models require bearings with an inner diameter of nearly 2 meters. The wind turbine industry is now an industry that develops on a global scale. Therefore, in addition to bearing manufacturing, marketing activities and technical services must be carried out at major outlets in the world. These are all important conditions.RDK is designing and developing more effective comprehensive solutions, including but not limited to: bearings, seals, condition monitoring systems and lubrication systems, etc.

Engineers work with original equipment manufacturers and wind farm operators to provide various specialized solutions to optimize the reliability and performance of new and existing wind turbine designs.

The advantages of wind energy solutions

Increase production capacity

Improve wind turbine performance and reliability

Reduce operation and maintenance costs

Reduce lubricant consumption

Reduce environmental impact

Reduce energy loss

Reduce warranty claims

Shorten time to market

Customized solutions

Parts can be sourced globally

Wind energy industry, applications, cases, solutions

Spindle

Whether it is a gear drive, hybrid or direct drive design, the main shaft configuration of the wind turbine must be able to withstand axial and radial loads, and be able to operate under constantly changing harsh conditions.

Gearbox

The gearbox needs to operate under a variety of conditions, and factors such as lubrication, load, stress, vibration and temperature vary widely.

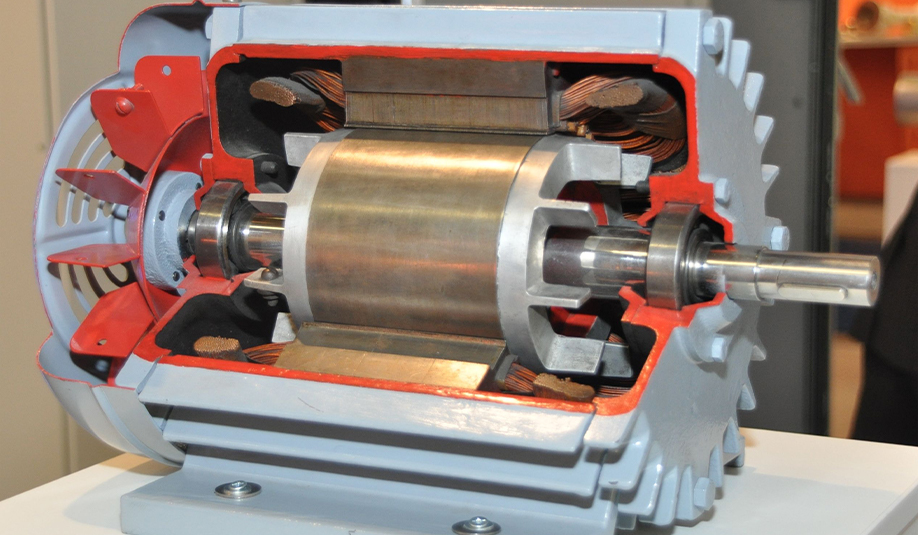

Wind motor

In a variable speed wind motor, the risk of bearing damage caused by stray current is very high. Designing solutions to protect the bearings is the key to the success of the new project.

Variable pulp and deflection

Pitch and deflection bearings, there is no ready-made solution.

Mountain slewing bearings can make full use of the existing wind power and optimize energy output, while reducing operating costs.

Calculation tools and finite element analysis help to understand the principle of interaction between different components and optimize the design of wind turbines.

Light nacelle design

Designing a light nacelle helps to improve the competitiveness of wind energy, especially for large wind turbines. Therefore, "power density" becomes more important. In short, it is the relationship between weight and energy output.