Analysis and Research on abnormal operation of vibrating screen

1. General situation

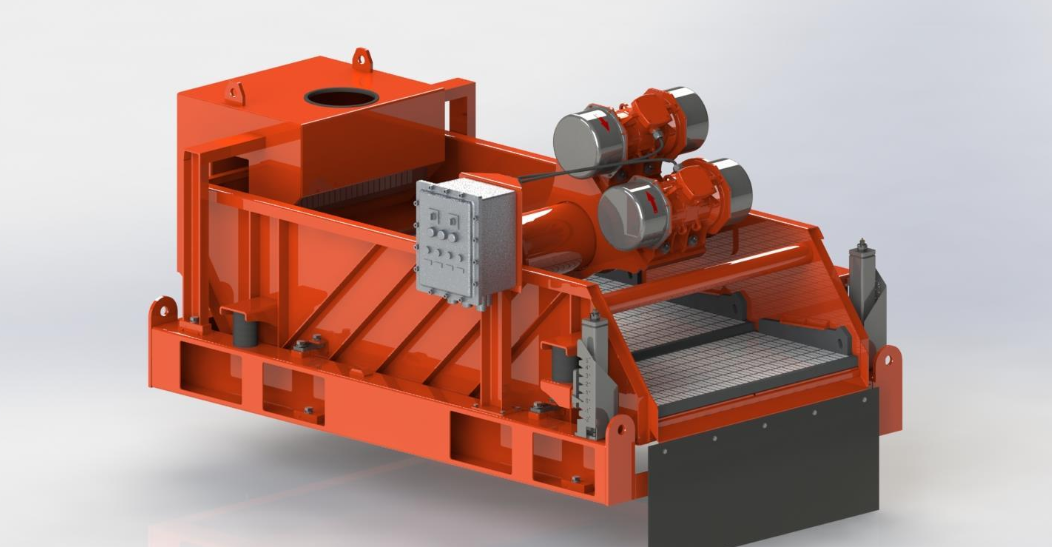

In the production system of coal preparation plant, many operations need screening machine to complete, such as preparation screening, inspection screening, final screening, coal dewatering, desilting and dielectric removal. There are many kinds of screening machines, such as fixed screen, roller screen, shaker screen, vibrating screen, cylinder screen, equal thickness screen, electromagnetic screen, etc. Because the performance of screening machine is required by coal preparation plant is high, it should have good functions of dewatering, desilting, dielectric removal and particle size grading, and the structure should be fine, so as to facilitate installation and maintenance management. According to this requirement, linear vibrating screen is widely used in coal preparation plant. The linear vibrating screen is composed of screen box, screen screen and vibration exciter. There are two ways of self synchronous drive of double motor and single motor pulley transmission. There are some problems in the use of sieve. Except for some mechanical faults, most of them are abnormal operation, such as different vibration direction angle, large yaw, large difference of four angle vibration spoke and material deviation, and some problems such as rotating and holding up of screen surface materials, which affect the normal operation of production.

2. Operation analysis

The causes of abnormal operation of vibrating screen are as follows:

① The vibrating screen is not installed correctly, the foundation is uneven, or the center deviation between the exciter shaft and the transmission shaft is too large (if the universal coupling is used, it is more prominent).

② There are foreign objects between the moving part of the vibrating screen and the movable part of chute and hopper.

③ The uneven feeding results in partial load, even there is no material on one side of screen surface.

④ The screen plate is not fixed firmly or damaged, resulting in secondary vibration.

⑤ The stiffness of the supporting spring at different positions is different or there is a fracture.

⑥ The working frequency of the shaker is the same as that of a certain natural frequency, and resonance occurs.

⑦ The vibration direction angle of two exciters is different, which will cause the vibration direction angle of two sieve plates not consistent.

⑧ The design of vibrating screen is unreasonable, the center of gravity is not in proper position, and the resultant force direction of the exciter fails to pass the center of gravity, and the deviation is large.

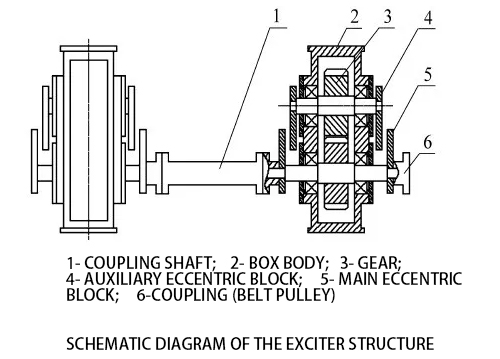

⑨ In the case of two box type vibration exciters connected with each other, the operation abnormality is easy to occur after several overhaul, such as torsional vibration, material deviation, screen side plate fracture, etc., mainly because the exciter is composed of two shafts with main and auxiliary eccentric blocks, and two identical gears are connected between the two shafts, as shown in Figure 1. This structure ensures the two shafts rotate in reverse direction at the same speed, and makes the excitation force on the two shafts overlap, and produces the exciting force with a certain angle with the horizontal plane. In fact, the resultant force direction of the excitation force is completely determined by the eccentric position of the eccentric block, that is, the correct position of the eccentric block is determined by the correct position of the engagement of the two gears. Because of gear engagement, the direction of resultant force and exciting force will change. For example, when the angle between the two exciters is included, the vibration screen will be torsional. Similarly, when the flange bolt holes at both ends of the transmission shaft connecting the two exciters are misaligned, the same situation is also caused. Therefore, when these conditions occur, the shaker will not operate normally, and the torsional vibration will cause great harm to the shaker.

3. Solutions

When the shaker is abnormal, the solution is to make a plan to adjust it in time according to the actual problems.

3.1 adjustment of installation level of vibrating screen

Whether the vibrating screen is installed horizontally is very important for operation. During installation and adjustment, the bottom surface of 4 support devices shall be taken as the benchmark, and the screen surface can be measured with a level gauge. The support spring base shall be added with pad to adjust it to meet the installation standard.

3.2 adjustment of the position of exciter and drive

The power of the shaker is realized by the connection between the transmission device and the exciter. The connection modes are as follows:

① The two motor drive is usually directly connected, and most of the coupling adopts universal coupling or CG type flexible rubber coupling.

② . the belt pulley is generally adopted for single motor driving. When universal coupling or CG flexible rubber coupling is used for transmission, it is generally allowed that the shaft of exciter is 2 mm higher than the transmission shaft. If the value or the gap between the flange is too large, it will cause the colloid to heat and twist the shaker. When adjusting, the sieve box can be leveled first, and the center of the input shaft of the exciter is slightly higher than the center of the flange of the transmission device, and at the same time, the gap between the two flanges is suitable, and then the coaxial degree is adjusted to meet the requirement. When using pulley to drive, the plane position of two pulleys should be ensured to prevent the vibrating screen from swinging due to the difference of plane position.

3.3 adjustment of torsional vibration of sieve plates on both sides

The main reasons for torsional vibration are as follows: the main reasons are as follows:

(1) The angle of eccentric block of exciter on both sides of screen plate is different, and there are three possibilities as follows:

① The angle between eccentric blocks is incorrect only on one side;

② The angle between eccentric blocks is not correct;

③ The wrong angle between eccentric blocks is caused by the reverse installation of gear reference surface.

(2) The two box type exciters are not connected correctly through the transmission shaft.

The above two conditions are the main reasons for the torsional vibration of the sieve. The vibration of the shaker can be judged by observation and marking method. After finding out the root cause of torsional vibration, the angle and position can be adjusted to eliminate.

3.4 incorrect adjustment of excitation force direction

For the cylinder type exciter, the problem of the direction of the excitation force is not correct, but the torsional vibration is rarely found. Because there is only one vibration source of this vibrating screen, it is relatively easy to solve the problem. When the direction of excitation force is incorrect, most of them are as follows: the amplitude of the shaker decreases, the movement track of materials changes on the screen surface, etc., mainly caused by the dislocation on the assembly of transmission gear, resulting in the dislocation of the main and passive eccentric shafts, as shown in Figure 2. In the figure, x, y are coordinate axes, PX and py are the decomposition forces in the x-axis and Y-axis directions respectively, and P0 is the resultant value of x-axis and y-axis under normal state. The resultant force direction of the eccentric axis is changed, which results in the weakening of the resultant force. Therefore, the gear should be marked before assembly, so as to avoid the abnormality caused by human error.

4. Conclusion

Because there are many abnormal operation conditions in the use of vibrating screen, some of them may be several abnormal superposition, so in the analysis process, the key points of the problem should be correctly judged, carefully disassembled and carefully adjusted to solve the problem, especially the self-developed and newly developed vibrating screen should be hard to design and manufacture. In order to improve the design accuracy, processing accuracy, structural performance and material life, at the same time, we should do a good job in the installation and adjustment, laying a good foundation for the normal operation of the vibrating screen.