Agricultural machinery bearing

According to the ever-increasing needs of modern agriculture/scale, location, altitude, climate, soil structure and crop rotation, each farm is unique. Agricultural equipment needs to operate under many similar challenging conditions, full of mud, dust, and debris; extremely hot and cold temperatures, rain washing, and sometimes corrosive chemicals. After a long period of inactivity, high-intensity operations are required. Rising fuel costs and new environmental regulations can only complicate the problem.RDK agricultural solutions can meet these needs

We understand the needs of modern farmers. We walked into their farmland together to discuss their challenges and concerns. We work closely with original equipment manufacturers to develop solutions to practical problems, and then verify the feasibility of the solutions on the working farm.

Agricultural Solutions has developed a series of solutions and services to help original equipment manufacturers and farmers meet the growing needs of the ever-changing industry. No matter what product it is, from complex combinations to specialized accessories.

The advantages of agricultural solutions

More robust and durable design

Simplified assembly

Provide differentiated products

Reduce warranty costs

End users benefit

Lower cost per hectare

Reduce maintenance

Extend the service life of the equipment

Reduce the use of fuel and grease

Higher degree of automation and precision

The equipment has higher working capacity

Improve safety and comfort

Agricultural industry, applications, cases, solutions

Combine harvester

After several months of inactivity, the combine harvester began its busy work schedule around the clock. Unplanned downtime during the harvest season can cause huge agency losses. Unfortunately, stressful operation and prolonged exposure to dust, severe vibration, and many other factors increase the risk of component failure.

We can help combine harvesters withstand the worse results caused by nature and work schedules. Our rugged and lubrication-free bearing and sealing solutions can increase running time when farmers need it more. When maintenance is required, the integrated bearing unit can speed up installation time. The solution can also help farmers adapt to changing conditions and crop needs.

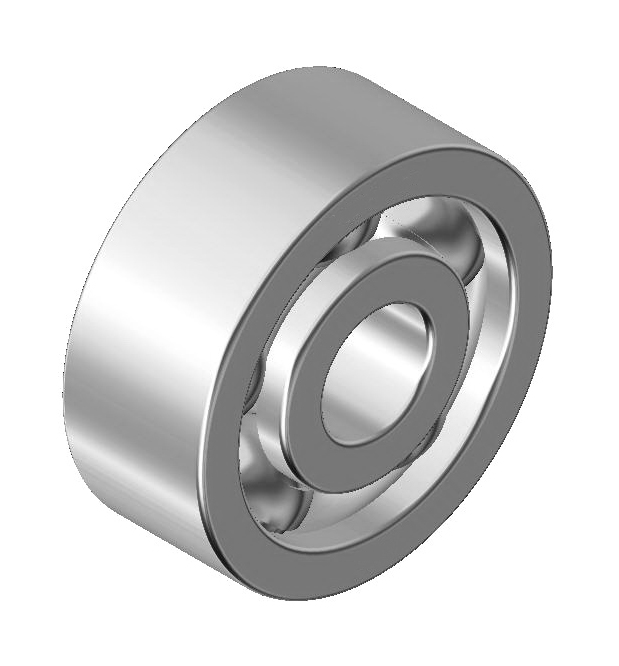

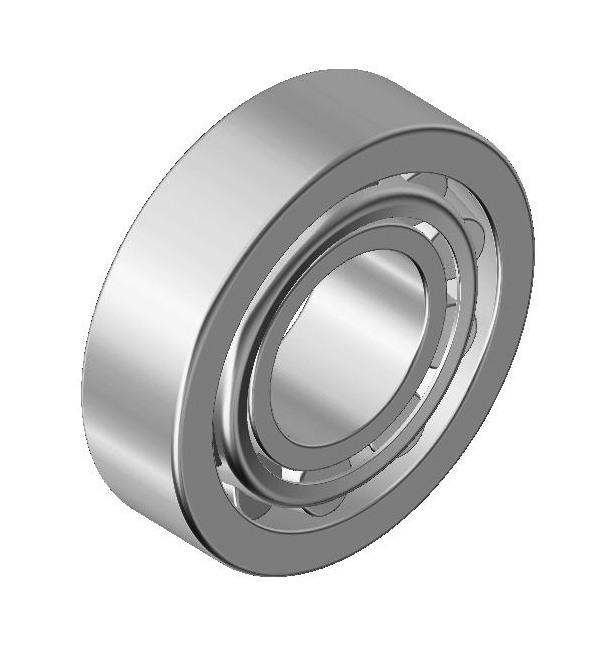

Disc harrow

Whether it is growing soil or mowing grass, the disc harrow must remove heavy and laborious soil, dust and more. Under working conditions, the disc harrow bearing must be in contact with these substances and bear heavy loads and shock loads at the same time. During the flushing process, the bearing seals must keep water and detergent from entering, and lubricants from leaking.

Sturdy and durable seal design and no need to re-lubricate the bearing unit help to maintain the disc harrow more reliably and easily, benefiting farmers and agents. The design of integral seals and bearings helps simplify the assembly line of the factory and reduce the installation time on site.

Disc lawn mower

Because the hay cut and prepared by the disc mower needs to be dried, unplanned downtime for maintenance or repair means that the output is reduced. Traditional bearing and sealing arrangements often cause such reductions in production due to gear particles or other contaminants entering the bearing. The ensuing lubricant loss, bearing failure, and costly troubleshooting will affect the safety and ultimate benefits of operators.

Sturdy and durable seal design and relubrication-free bearing unit are designed to be more efficient and easier to maintain, and can help prevent unplanned shutdowns. The rake device has been tested and can withstand heavy vibration and harsh field conditions. These integrated and compact units can also help original equipment dealers reduce components and accelerate assembly.

Packing machine

Many bearing arrangements rotating in the baler unit must endure a series of dust, dirt, straw and other contaminants. Farmers and original equipment dealers need these bearings to operate reliably and with as little maintenance as possible. They are all looking for ways to improve the quality and accuracy of the baler.

Agricultural solutions make the operation of the baler device more reliable, efficient and efficient. Rugged and durable seal design and maintenance-free bearing unit can reduce the need for maintenance and lubrication. Compact electromechanical actuators can help better control the quality of packaging, while the engineering consulting service department can help original equipment agents adjust and optimize the packaging process.

Tractor

Improve power density and reliability. Reduce fuel consumption and carbon dioxide emissions. Better ergonomics and more "smart" agricultural farming capabilities. In order to effectively meet these increasing demands, agents are looking for suppliers to develop innovative solutions. We can help.

Can provide original equipment dealers with a series of more components and systems, including from cabins to power transmission systems to parking brakes. Helps simplify tractor design, thereby providing higher fuel efficiency, operating comfort, GPS control and more.

Seeder

After being idle for a long period of time, the planter is again put into the harsh environment for intense work. Bearings can ensure that they can still effectively plant seeds in harsh environments where they are exposed to dirt, dust, detergent and moisture. Contaminants can cause bearing failures and costly unplanned shutdowns.

In order to ensure a higher profit margin, the seedling planter must also sow as accurately as possible. Computer-aided actuation systems can ensure accuracy, but these components must withstand harsher environments.

With agricultural solutions, original equipment dealers are designing more reliable and effective next-generation seedling planters. Rugged seal design and maintenance-free bearing unit can reduce the need for maintenance and lubrication. The compact electromechanical actuator can use seeding technology, and the engineering consulting service department can help the original equipment manufacturer meet any requirements.

Sowing and fertilizer applicator

Like the seedling planter, the seeding and fertilizer applicator should be idle for several months, and then work hard day and night for a period of time. Bearings and other key components, including fertilizer applicators, face a series of harsh environments and possible pollutants. All of these can lead to bearing failures and costly unplanned shutdowns.

In order to help ensure higher crop yields, seedling planters must also perform extraordinary seeding. Computer-aided actuation systems can reach this level, but these components also need to withstand harsh field conditions. To be successful in the market, the cost of this "smart" agricultural solution must also be affordable for farmers.

Agricultural solutions help original equipment agents to develop more reliable, effective and competitive seeding and fertilizer applicator devices. Rugged seal design and maintenance-free bearing unit can reduce the need for maintenance and lubrication. The compact electromechanical actuator can achieve a higher degree of fertilizer application. The Engineering Consulting Services Department can help original equipment agents optimize their designs to meet the specified requirements of customers.