Design factors and optimization of RDK ultra high speed deep groove ball bearing

With the rapid development of hybrid electric vehicles and electric vehicles, the requirement of environmental protection is that the motor is smaller and lighter. The smaller size of the motor, its output power will be reduced, but in order to ensure the same or higher output power with the current engine, it needs to use a higher speed motor. RDK ultra-high speed deep groove ball bearing is used to analyze and optimize the motor in order to withstand the speed of more than 30 000 R / min.

Analysis of influencing factors

1) Lubrication

Choose oil lubrication method. Due to the high-speed rotation of the rolling element and cage, a large amount of lubricating oil will move to the outer diameter of the bearing under the action of centrifugal force, and the lubrication between the inner ring and the rolling element or between the rolling element and cage is insufficient. Insufficient lubrication will cause the internal parts of the bearing adhesion, leading to the bearing stuck. Increasing the solution of lubricating oil will increase the resistance and torque produced by oil stirring.

Internal state of bearing under high speed operation

2) Friction

Friction between ball and channel surface

When the RDK deep groove ball bearing rotates, the sliding friction between the ball and the groove surface is proportional to the rotation speed of the bearing. The effect of sliding friction can be ignored at normal speed. However, it is very important to control the friction between the ball and the raceway surface at ultra-high speed, because the rapid increase of friction will lead to the increase of bearing heat.

Friction between ball and cage

Stamping steel wave cage and plastic crown cage are commonly used in deep groove ball bearings. The stamping steel cage is made of two halves which are punched into waves and riveted with ball pocket structure; the plastic crown cage is made of nylon resin reinforced with glass fiber. Both cages are provided with a spherical pocket with a locking mouth, and friction will occur between the ball and the cage pocket. At normal speed, the force acting on the ball and cage is very small, and the friction at the cage pocket is as negligible as the friction between the ball and bearing ring. However, under the condition of 30 000 R / min ultra-high speed operation, the circular velocity of the ball can reach 40 m / s or even higher, and the point stress between the ball and cage increases. Plastic cages are self-lubricating and light in weight, so they are more suitable for high-speed operation than stamping steel cages. The friction between ball and cage pocket will increase the wear of pocket surface, even the cage may come out of the bearing.

3) Cage strength

Choose plastic crown cage. When the plastic crown cage rotates at high speed, the outer surface of the cage will deform under the action of centrifugal force. At this time, the cage will contact with the outer ring of the bearing. When the cage contacts the outer ring of the bearing, the temperature rise of the bearing increases. In addition, the cage with large deformation will fracture due to the excessive stress on the circumference of the pocket. It is necessary to develop an enhanced cage structure, which can withstand the cage deformation and damage caused by centrifugal force. The strength of the cage can be improved by increasing the cage wall thickness, but the bearing width can not be increased.

Optimization and improvement

1) Install the cover to control the oil flow

By installing the cover to prevent the lubricating oil from overflowing to the end face of the bearing, the internal lubrication of the bearing can be sufficient, and the problem of insufficient internal lubrication of the bearing under the action of super high speed centrifugal force can be solved.

2) Reduce friction

The sliding between the ball and the bearing ring is reduced by optimizing the groove diameter and ball diameter. By improving the lubricity of the pocket surface and reducing the impact force between the ball and cage, the wear of the pocket surface can be effectively avoided. By adjusting the clearance between ball and cage pocket and the clearance between inner ring outer diameter and cage inner diameter, the impact force and wear between ball and cage can be reduced.

3) Improve cage strength

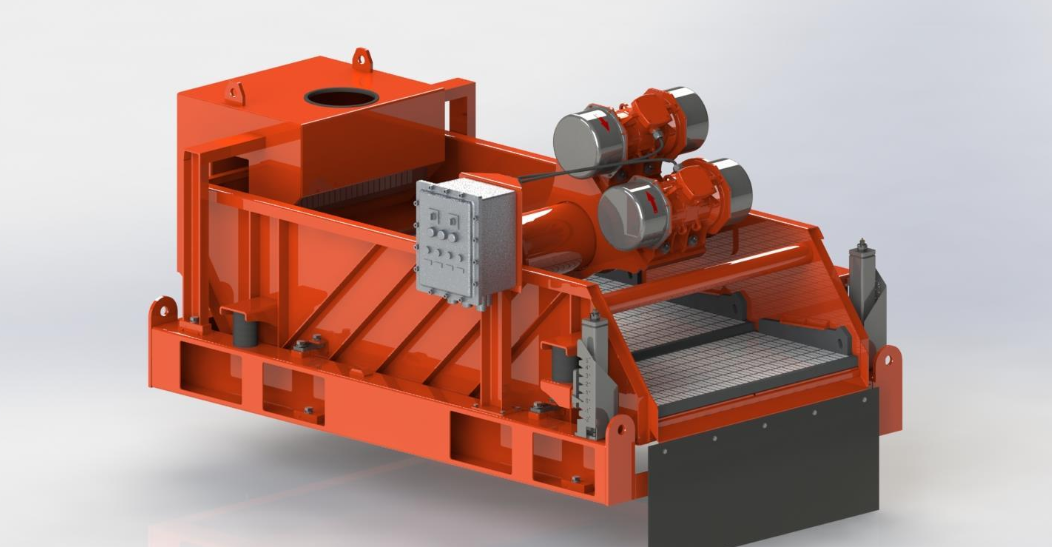

Increase the wall thickness of the existing cage, improve the stiffness of the cage, reduce the deformation of the cage under ultra-high speed operation, and avoid excessive stress on the surface of the cage pocket, resulting in fracture. The profile of the newly developed bearing is shown below.