Railway

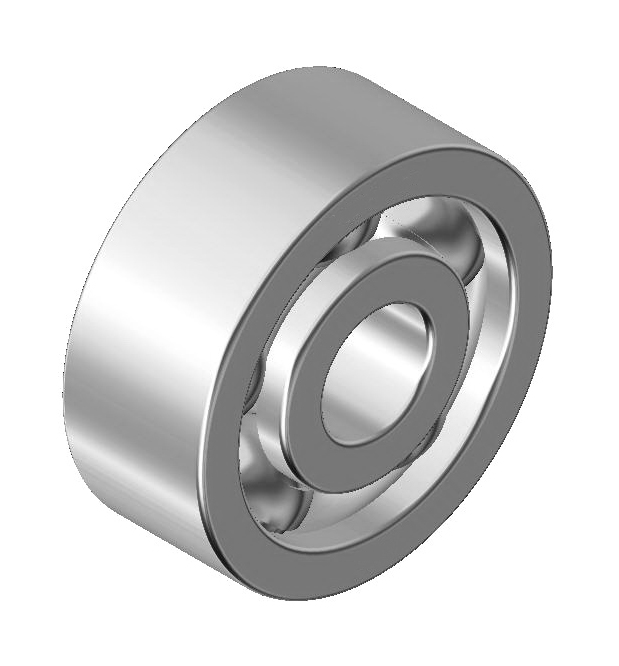

RDK has rich experience in the development and production of railway bearings, railway passenger and freight, and traction motor bearings.RDK mainly produces special bearings for high-speed railways, quasi-high-speed passenger transport, freight, traction motors, subway and light rail trains, including: quasi-high-speed railway passenger bearings and heavy-duty truck bearings. Our railway-specific products and services allow you to take full advantage of the performance potential of bearings, thereby helping you reduce life cycle costs.

Application areas:

subway

Traction car railway

Freight Railway

Passenger Railway

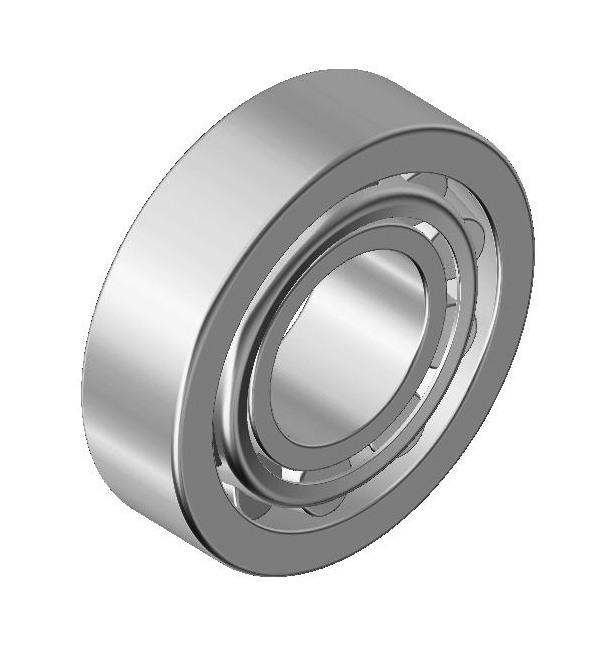

Bogies are complex railway vehicle subsystems, which are essential to ensure the reliable operation of trains on the track.

Ensure the stability and ride comfort of rail vehicles. The bogie is a complex railway vehicle subsystem, including the brake system, drive system, wheel subsystem and bogie frame with auxiliary spring system. Although different bogies are designed for different purposes, they have the same function. This includes supporting the body of the rail vehicle to help ensure the stability of the vehicle on the track and provide ride comfort. Connected directly to the wheelset and the bogie frame is the axle box, which contains the axle box bearing system, which is connected to other subsystems and components.

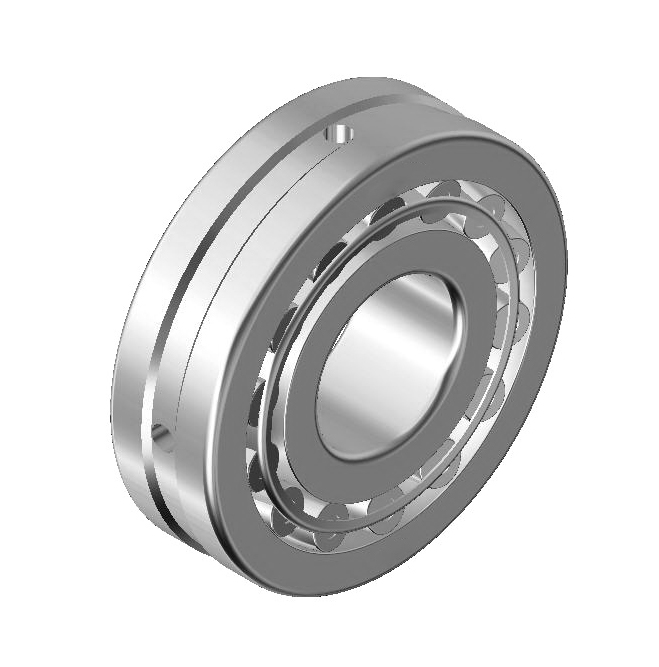

Drive system bearings can achieve low-maintenance, sustainable, and cost-effective railway operations in humid environments, constantly changing speeds and loads, and high pollution.

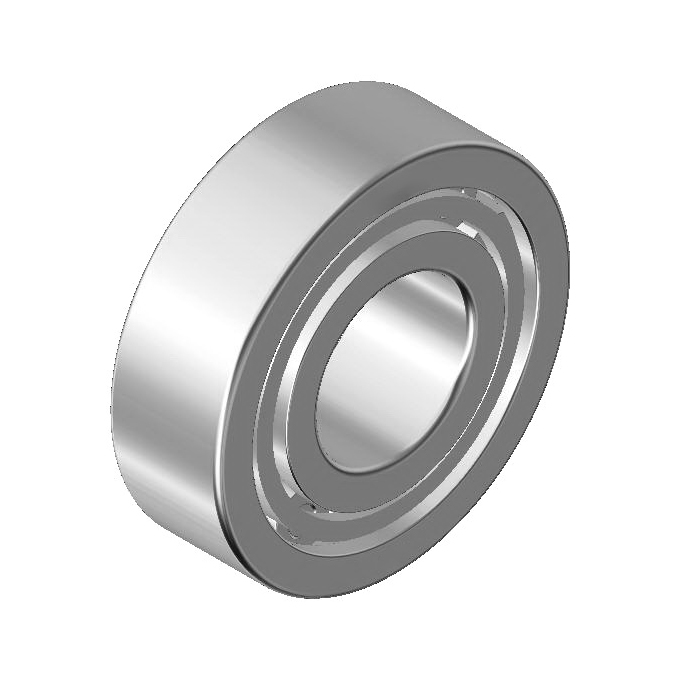

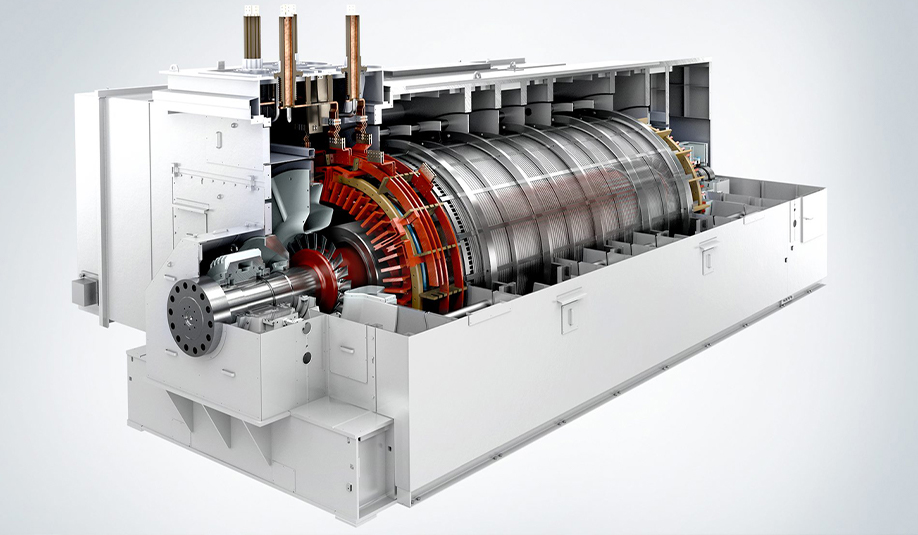

To achieve robust, sustainable and cost-effective railway operations, drive systems used in railway trains, such as gearboxes or traction motors, must have the characteristics of powerful, sustainable, cost-effective, and low maintenance requirements. As maintenance intervals are getting longer and the weight of railway vehicles is increasing, these requirements are becoming more and more important.

The traction motor must provide high speed and withstand shock loads, and must also resist low load conditions, such as in coasting or cruise control mode. In addition, the sensitivity to electrical discharge also makes traction motor bearings face unique design challenges.

The design requirements of the gearbox also put forward high requirements on the gearbox bearings and bearing arrangements. Specific challenges include a wider operating temperature range, high shock loads, and an increase in the overall load combined with the drive to reduce friction in the gearbox and reduce energy consumption.

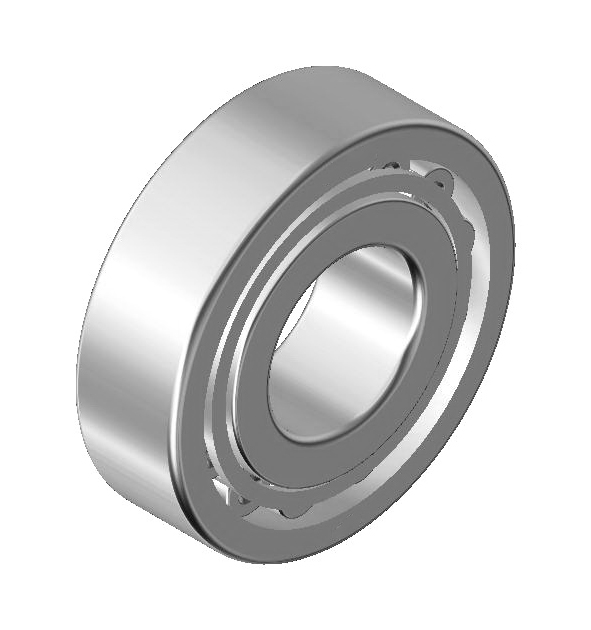

Track solution

Track conditions play an important role in the reliability of railway operations.

Poor track conditions may have a negative impact on key components such as train wheelsets or wheelset bearings, so good maintenance solutions are required. However, this is not an easy task due to the need to inspect, maintain and fix hundreds or even thousands of kilometers of railways.