Bearing in power plant

For today's power plants, efficiency and reliability are the keys to success. In order to achieve this goal, coal and combined cycle power plants are looking for ways to optimize output, regardless of whether they increase fuel and maintenance costs, reduce manpower, and face more stringent management regulations.Older power plants are restricted by aging equipment and fewer experienced employees. Newer power plants require technology sharing in order to reduce manpower at least while not posing risks to plant assets or personnel.

RDK power generation solutions can help

With years of expertise in the field of rotating equipment, we have always provided support for the performance and reliability of power plants in the past. Today, various comprehensive solutions are provided at the same time to help factories:

Increase production

Optimize maintenance

Extended service life

Improve safety

Reduce operating costs

Power generation industry, applications, cases, solutions

water supply system

In the process of power generation, it is very important to keep the water flowing from the condenser to the heat recovery steam generator (HRSG) steadily. These include multiple devices that operate normally at higher and higher temperatures and pressures.

Circulating water system

The circulating water system has two core functions: filter the water pumped to and through the condenser, and keep the condenser cool.

Condensation system and water make-up system

The use of make-up water to condense the steam in the steam turbine and circulate the steam to the boiler feeder is another key operation step of the combined cycle power plant.

This is another situation where pumps and motors are affected by high temperatures and pressures that can cause failures, unplanned shutdowns, and costly shutdowns.

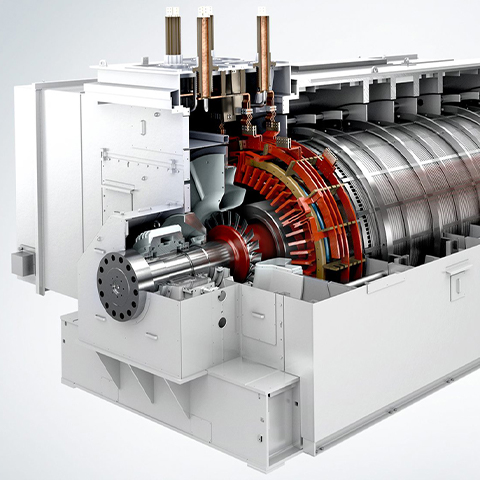

Steam and gas turbines and auxiliary equipment

The process of converting high-temperature, high-pressure steam into alternating current is impressive. Even more surprising is that in the face of demanding application requirements, that is, rising maintenance costs, reduced human resources, and increasingly stringent regulations, reliability and profitability can also be obtained.