Mining and mineral processing

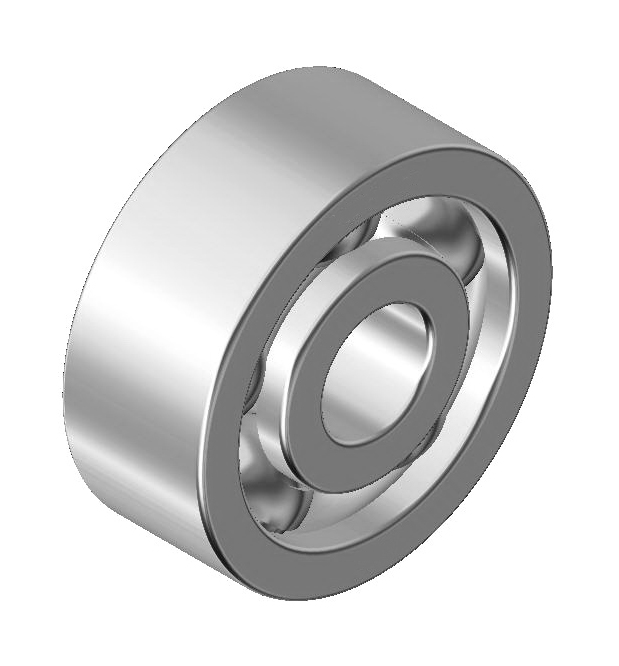

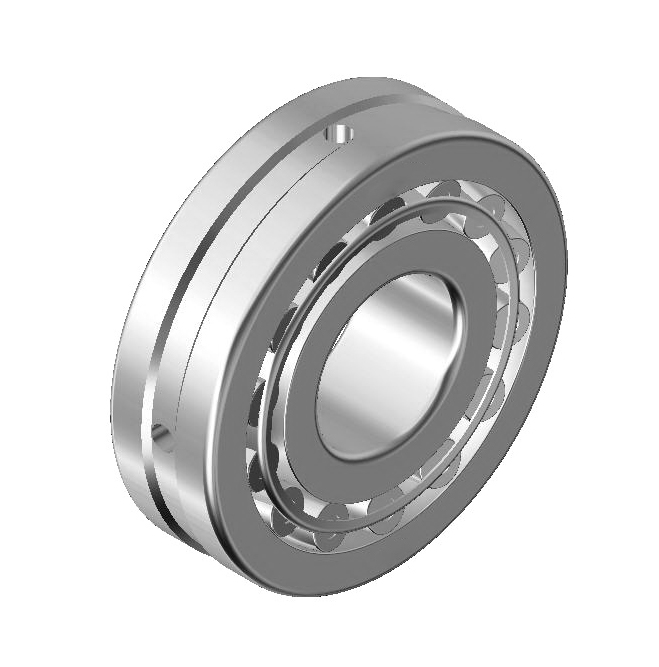

Heavy loads, wear debris and dirt, extreme temperatures and other extreme conditions. These conditions make it very difficult and even dangerous for mines and cement plants to keep their machines running continuously. The risk of worker injury and unplanned downtime always exist. Extremely harsh working environment requires bearings with very good performance. In addition, although the global demand for metal ore, cement, and coal is increasing, high costs and strict regulations have forced them to reduce energy consumption. RDK's continuous research and development and extensive exchange of experience between machinery and equipment manufacturers and operators have shown that the operational reliability and service life of RDK bearings have been continuously improved.Mining and mineral processing solutions can help

Provide high-quality products and solution services to help reduce the total cost of ownership of equipment at each stage. From technical specifications and design to operation and maintenance, it is a mature management method. The provided solutions help mining and mineral processing operations:

Improve production efficiency and profitability

Improve the safety of workers

Reduce the impact on the environment

Reduce energy consumption

Reduce unplanned downtime

Mining and mineral processing industries, applications, cases, solutions

Mining and quarrying

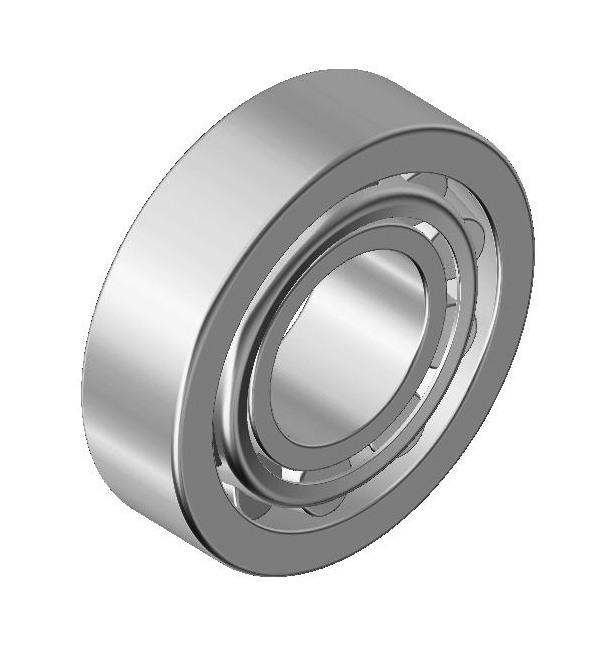

The climate ranges from the cold of the district to the extreme heat of the desert. The altitude spans from 4300 metres above sea level to 3800 metres below ground level. Severe weather and abrasive contaminants caused great damage to these equipment and workers. Conditions such as these require equipment and suppliers you can rely on.

Mineral agent

For agents of aggregate, coal, metal ore and industrial minerals, the key to their profitability lies in maintaining high work efficiency and low costs.

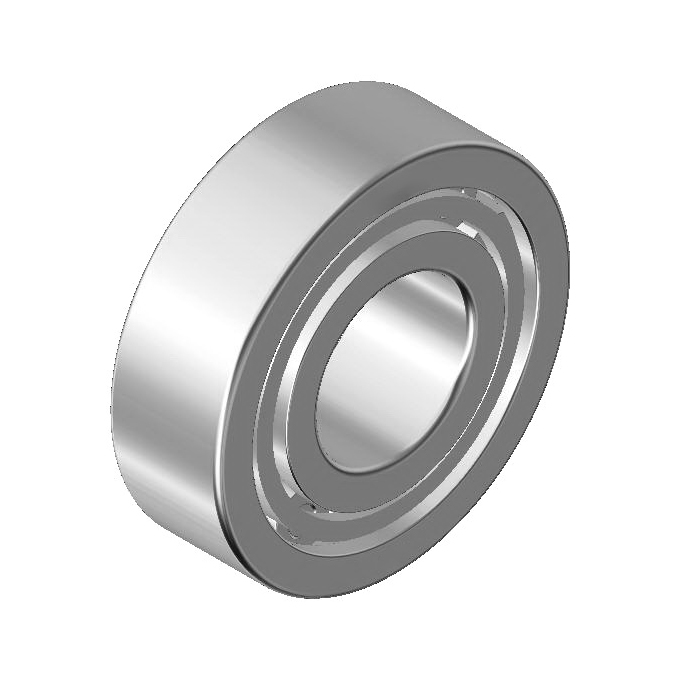

Reliability and safety are the keys to achieving uptime and plant profitability. The equipment must be kept in good condition and able to cope with harsh working conditions.

Cement agent

Like other mining plants, cement plants also have to deal with the harsh conditions brought about by crushing, conveying, vibration and grinding applications.

Cement plants must also resist the end temperature caused by the rotary kiln and cooler. Maintenance of various auxiliary fans, compressors and pumps is also critical. High energy costs and new environmental regulations pose further challenges to agency power.