Bearing for aviation industry

Aerospace provides a variety of aerospace solutions, including bearings, seals, tie rods, struts, precision elastic devices, and fly-by-wire control devices for airframes, aero engines, and gearboxes. Provide services to various customers in the aerospace industry and support them in the development of new projects. From major customers original equipment manufacturers (OEM) to maintenance repair and overhaul (MRO) companies, we can also provide them with reliable spare parts, complete overhaul services, and high-performance alloy steels for aerospace applications.RDK provides you with innovative solutions with many years of experience in aerospace.

Aerospace industry industry, applications, cases, solutions

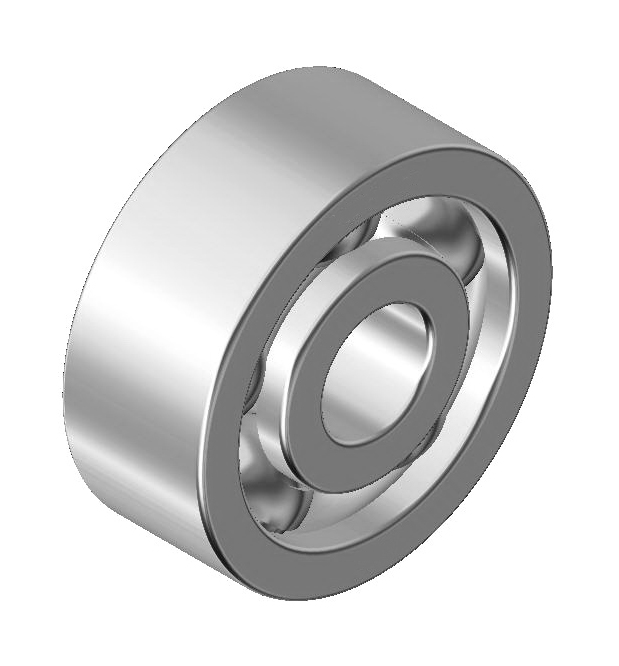

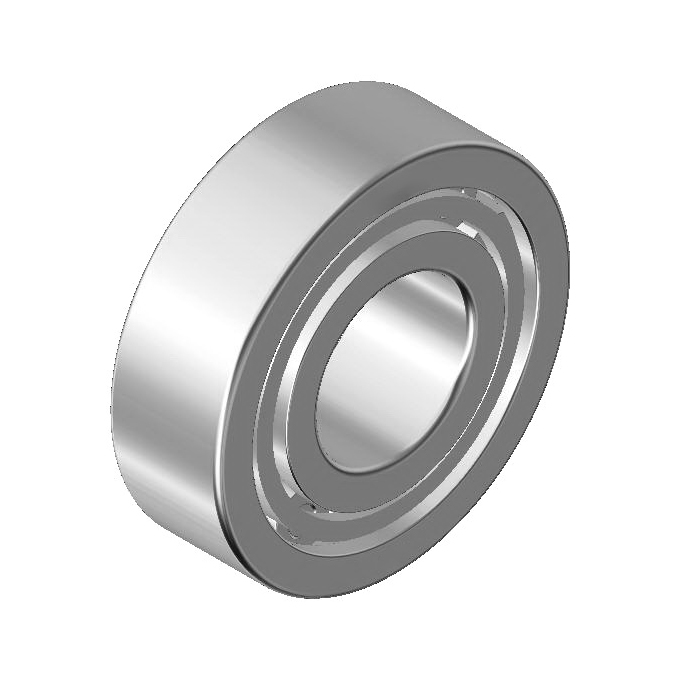

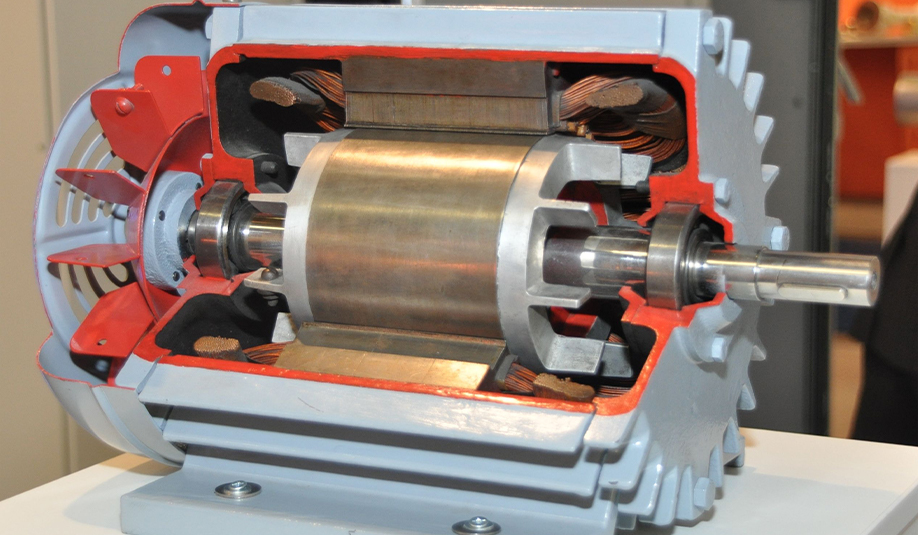

Aero Engine Bearing

Aerospace ball bearings and roller bearings must operate reliably under harsh working conditions. Therefore, in aerospace applications, selecting bearings that can provide better performance is a complicated process. This requires a thorough understanding of bearing design, materials, lubricants, operating speed, temperature limits, agency capabilities and quality requirements.

Designed in accordance with the application requirements specified by customers, each aero engine product is made of better quality materials.

The steel used for bearing rings and rolling elements is made by vacuum pumping or vacuum melting technology, so its cleanliness and homogeneity are very high. All materials must pass metallurgical, chemical and mechanical inspections. The materials used for the aero engine bearings are heat treated in a smelting furnace that meets the standards and under strict metallurgical control. When heat-treating the high-temperature and corrosion-resistant steels commonly used in aero-engine bearings, a more advanced vacuum furnace must be used, with compressed nitrogen quenching and afterburner convection heating treatment technology. These vacuum furnaces achieve a more precise thermal cycle through greater control capabilities.

Aero-engine quality control personnel use a better surface analyzer to determine the straightness and roughness of the bearing raceway. Electromechanical instruments are used to determine the structural characteristics such as the location of the holes. Use non-destructive testing technology to determine the surface and sub-surface defects of the finished bearing components.

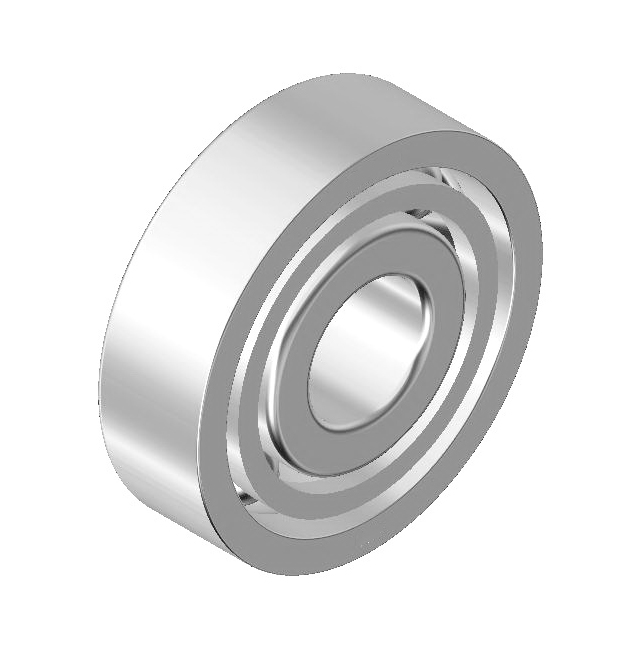

Airframe bearing

Cooperate with a company that can provide a full set of solutions to optimize your supply chain strategy. This also means that you can use the current updated technology to find a better solution for your application. A wider range, even more polluted environments, to meet your needs for visual control or maintenance-free. Since we have a close relationship with customers and understand their needs very well, we can provide more appropriate solutions. Committed to finding a better solution for your application, and always maintaining a better position in the development of new technologies for body bearings. At the forefront of technological innovation, we are committed to providing many technologies and a wider range of solutions. work...

Tie rods and struts

New aircraft require higher technology to achieve sustainability challenges and reduce direct operating costs. At the same time, the aerospace market is changing with each passing day, prompting aircraft designers to meet more requirements in a shorter period of time.

Over the years, continuous improvement and optimization of the better strength/weight ratio of tie rods: composite or metal swaged pipes. Nearly 10,000 tie rods have been sold, and we have a wealth of knowledge and engineering capabilities to meet your more stringent requirements.

Tie rod series can be used for all types of applications and raw materials, showing a strong competitive advantage in engineering. Based on our long-term experience and rich knowledge in tie rod engineering technology, we can help you build larger, lighter and more efficient aircraft.

is committed to becoming your partner, meeting all your requirements for tie rods, and also successfully implementing a set of powerful solutions to improve the entire supply chain. In addition to electronic data exchange functions and a shared network platform, supporting solutions and customer services have improved the efficiency of the aircraft assembly line team's collaboration.

Helping to reduce weight is one of the main goals of our engineers. As the metal tie rod achieves a higher strength/weight ratio and uses more effective raw materials to develop its terminal accessories, it can optimize the total weight of your application. Weight reduction means that fuel consumption will also be reduced, so as to achieve sustainable development and more economical aircraft.

Composite material solutions

Modern aircraft increasingly use composite materials. Is it just because composite materials can reduce the weight of aircraft? Or is it because composite materials can represent aircraft and helicopters that are more comfortable, longer range, larger, and longer lasting? Are you only interested in composite technology, or do you want to be A partner who designs and develops efficient solutions together?

Works closely with major aircraft agents and is at the forefront of composite material technology research and development. This means providing better technology to reduce direct operating costs and achieve sustainable development. Years of experience in the agency of composite tie rods shows the ability and sustainable development capabilities in this field.

Support the framework with the concept of struts, and by providing solutions to reduce weight, it helps reduce aircraft operating costs and promote sustainable development.

Therefore, composite material technology is provided in all types of applications: flight control rods, structural struts and rotating rods, independent ends, fixed or adjustable rod ends, simple or integral fork ends, or any other ends .

Composite material technology reduces weight while also providing a high ratio of mechanical properties/density. To meet the stringent requirements of the aviation industry.

Through the establishment of a solid partnership with customers and the support from customers, we have developed innovative supply chain solutions to improve the efficiency of the assembly line and shorten the delivery time.

From R&D solutions to certification testing, an experienced team of engineers is committed to providing support to customers to meet the more demanding aviation industry requirements.

Wire control system

We are continuously integrating various functions, including automatic throttle and driving side stick.

Position and force conversion device

Linear and rotary actuators

Artificial touch and ergonomics

High-precision mechanical device

Integrated cockpit sensors

The interface between the pilot and the flight control computer

Control the aircraft during taxiing, take-off and landing

Control the forward and reverse propulsion power of each engine

Spoiler and speed brake operation

Facility actuation applications: doors, air cooling...

Basic electromechanical core

The same design applies to any aircraft

Simple and reliable

Analog or digital output for full digital electronic engine control

Data bus used for flight management system, namely: arinc 429

Special discrete signal output

button

The cockpit is designed according to customer requirements

Leather, wood or plastic panel

Handle color and shape

Friction feedback of the handle

Number and strength of dents

button

Auto throttle capability

By using a simple automatic thrust override control device, the aircraft can fly round by round

Better ergonomics

Smooth and constant friction

Provide and stable interception speed

Reduce pilot workload

more comfortable

Fly safer

Lower fuel consumption

Precision elastic equipment

Today, lowering direct operating costs (DOCs) and improving efficiency have promoted the design and development of new aircraft. In order to achieve these goals, the aircraft agent’s solutions must not only make the aircraft lighter, but must also achieve a more compact structure, a longer service life, and improve maintainability.

Provide better technology for major aircraft agents, and become a key success factor for being at the forefront of flexible technology.

We are honored to have many years of experience in R&D, design and formulation of flexible solutions. This shows continuous research and development, keeping promises to help you achieve your goals and support your time to market.

From R&D application solutions to quality testing in our own test laboratory, the experienced team of engineers is committed to providing you with support to meet the more demanding aerospace requirements.

Choose materials from a variety of high-quality elastic formulas, and can also develop special rubber synthetic materials that meet your requirements. By optimizing the application, design and formulation of its flexible solutions, it creates a more robust and durable technology.

By reducing the number of applied parts and adopting weight-reducing technologies, elastic bearings help reduce weight and represent a more sustainable aircraft. It can also significantly reduce DOCs and improve sustainability by improving your current applications.

Compared with traditional solutions, elastic solutions can reduce weight and better resist dusty or humid end environments.

In addition, its visual inspection and replacement standards according to the situation enable flexible solutions to significantly reduce the maintenance and condition monitoring of your application, thereby reducing the aircraft's DOCs.

Compared with the traditional hub, 74% less parts

Weight of axle hub reduced by 20%

50% longer service life

Maintenance cost reduced by 75%

Seals

We apply our unparalleled expertise to flexible technology to help engineers produce quieter, smoother, safer and more reliable products. We are solving specific problems in aerospace applications by customizing formulations, synthesis, molding, and welding of elastic products under precision engineering design.

Radial lip shaft seals, gaskets and seal covers for rotor systems, auxiliary power units, engines, gearboxes and transmissions.

Customized design, can be used to bear heavy loads when large deviations of absorption, damping and/or control occur simultaneously in several directions.

Achieved by layered elastic elements between the base sheet caulking pieces.

Integrate multiple components into the same device, requiring only minimal maintenance; no lubrication is required.

Supported by a wealth of design, testing, agency and quality control equipment.

Carbon seal

This is especially true in aerospace applications.

Drive System

Among all the solutions developed, the solutions regarding actuation are more diverse. From tie rods or fly-by-wire control equipment used for door actuation, to body bearings on the wings, we can provide a solution that suits you.

Body structure

Improve the more important parts of the aircraft structure, such as the overall weight or mechanical specifications of some components such as struts or body bearings.

Engine and gearbox

Aero engines and gearboxes are demanding applications that require high reliability and tight tolerances.

For many years, it has been responding to these challenges with products and services, and is an important engine and gearbox agent.

Flight control

Can provide a complete solution from the joystick or throttle control device to the mechanically actuated aileron or spoiler to optimize flight control.

Landing gear

The application requirements of the landing gear are very high, because it is completely hydraulic to support the weight of the entire aircraft. To help you achieve this goal, we provide a complete set of lightweight and easy-to-install solutions.